HydroDrill®

Got scale? No problem! These water powered drills will even clear tubes plugged solid with hard deposit.

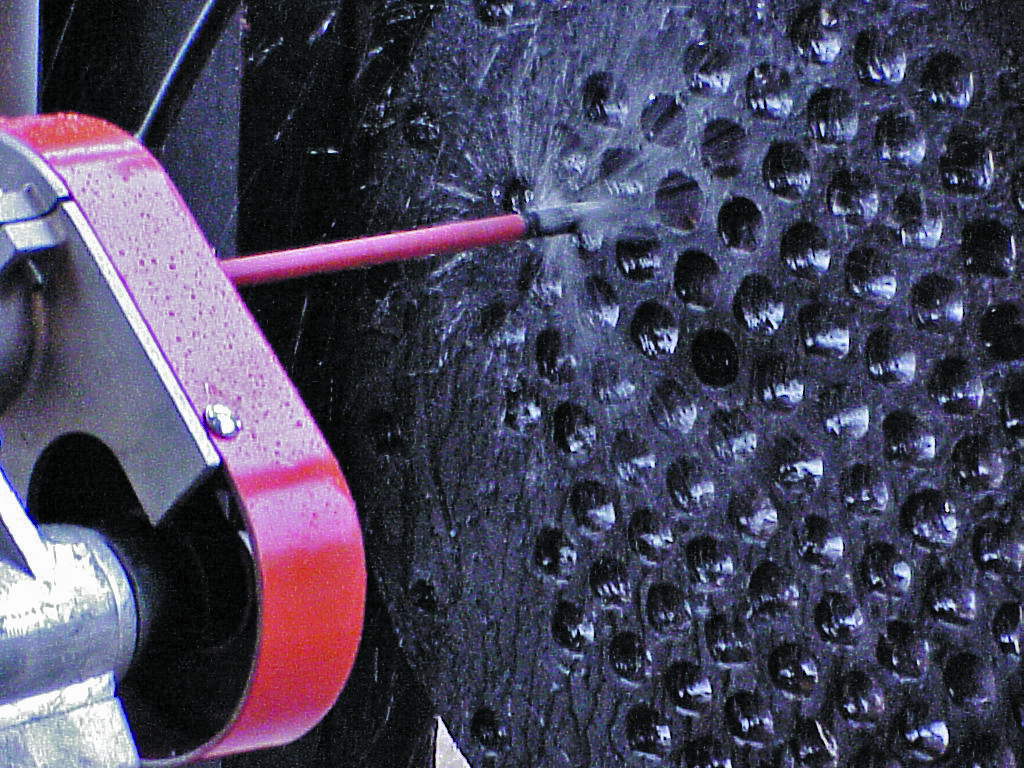

Designed to solve the most difficult tube deposit problems, Conco HydroDrills™ combine powerful rotary tube cleaning action with a 2 to 3 GPM water flush to clear even completely blocked tubes. They are ideal for cleaning all types of heat exchangers including chillers, oil coolers, condensers, and process manufacturing tubes. Sized properly, the heavy-duty Dominator and hand-held Mitee Mouse II units are designed for maximum cleaning effectiveness. Depending on the system used, Conco crews can remove obstructions from any type of tube ranging from 1/2” to 2-1/2” O.D. and up to 60’ in length. Completely blocked tubes can be restored to 100% of the original tube I.D. HydroDrill tube cleaning is fast, typically clearing 20-foot-long tubes in only 30 to 90 seconds each.

In the field, the HydroDrill system has been used to clean process fouling on the same exchangers over a thousand times. The system can even accommodate tubes that are bowed, since the long, slender Kelly Rod or Extension Rod that drives the bit inherently bends to follow the tube. Both the Dominator and Mitee Mouse II HydroDrills are easy to set up and operate. A Conco crew can be in-the-cut in less than one hour. In the last 30 years, the HydroDrill system has successfully cleaned thousands of heat exchanger tubes, worldwide.

HydroDrills are used to remove hard tough deposits including:

- Coke

- Calcium

- Sulfur

- Bauxite

- Alumina

- Asphalt

- Oxides

- Polymers

How It Works

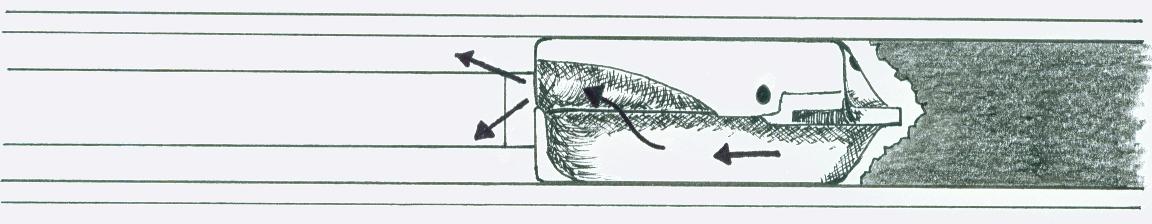

All HydroDrills use a brush or drill bit mounted to the tip of a rotating Kelly Rod or Extension Rod and a water flush to remove debris. As the rod rotates, the unit pumps water through the rod to weep holes in the cleaning tool, flushing away hardened deposits as they are loosened.

HydroDrill cleaning is safe for all tube materials. Drill bits are sized to be 0.005” below the minimum tube I.D. They feature long shanks to ensure that the axis of the bit and the axis of the tube are in complete alignment. The bits are designed with carbide tips on the leading edge only and with rounded corners to ensure no sharp edges directly impact the tube wall. The drill also rides on a thin layer of water for lubricating bearing surfaces between the bit and the tube. HydroDrills have been used repeatedly to clean process fouling on some heat exchangers over 1,000 times – with no tube damage or degradation!

Features

- Safe low-pressure water (200 to 300 PSI)

- Low volume water flush (3 to 7 PSI)

- Foot pedal and hand lever to control shaft rotation, linear motion and water flow

- Small footprint (50 to 100 sq. ft.)